Service Hotline

0769-82101656

Today, when integrated circuits are commonly used in electronic components, it is particularly urgent to solve the large amount of heat generated by the integration of chips. Everyone knows that high temperature is the natural enemy of electronic products. It will not only lead to unstable performance of electronic products, but also greatly reduce the service life. Portable electronic products may even cause damage to human body due to high temperature. Therefore, our electronic product structure design engineers need to optimize the structural design, and then choose the thermal conductive interface material with good thermal conductivity to help the chip quickly and efficiently conduct a large amount of heat out, ensuring that the electronic products can be in a safe temperature range. Stable operation.

The heat dissipation method can be divided into passive heat dissipation and active heat dissipation.

Active heat dissipation: The fluid is circulated by external force to remove heat.

Passive heat dissipation: It is the principle of thermal expansion and contraction of physics. The fluid naturally circulates heat or uses the specific heat capacity of the solid fluid to absorb heat to achieve heat dissipation.

The heat dissipation method can be subdivided into heat conduction, heat convection and heat radiation.

Heat conduction: The phenomenon of heat transfer in a medium without macroscopic motion, heat transfer from one part of the system to another or from one system to another, which can occur in solids, liquids and gases.

Thermal convection: refers to the relative displacement (convection) between the various parts of the fluid caused by the macroscopic movement of the fluid. The heat transfer process caused by the mixing of the hot and cold fluids can be divided into forced convection and natural convection. Forced convection is due to the circulation of fluid generated by external action. Natural convection is due to temperature gradient changes of different densities. Gravity causes low-temperature high-density fluid to flow from top to bottom, and high-temperature low-density fluid flows from bottom to top.

Thermal radiation: It is a heat transfer method in which an object radiates heat outward in the form of electromagnetic radiation. It does not depend on any external conditions.

Principle of thermal design

1, reduce heat

That is to choose better control methods and technologies, such as phase shift control technology, synchronous rectification technology, etc., in addition, select low-power devices, reduce the number of heat-generating devices, increase the width of rough printing lines, and improve the efficiency of power supply. .

2, strengthen the heat

That is, the heat transfer is carried out by conduction, radiation, and convection techniques. However, for products with a flat appearance, first of all, it is impossible to use more heat-dissipating aluminum sheets and fans from the space, and it is not allowed to enhance the cold heat-dissipation design as a whole. The convection form cannot be used. The same way of radiating heat is also difficult to achieve in a flat space.

Six types of heat dissipation methods for gun cameras:

1. Reduce the current. The use of low-power infrared lamps instead of high-power infrared lamps, although reducing the amount of heat, but when irradiated long distances, the effect is certainly not as good as the latter.

2, in the array infrared gun-shaped camera inside the cooling fan, the effect is certainly there, but the test of the fan is very strict, and the addition of a fan for the design of the shell is also a test, to ensure the beauty Be practical.

3. Use a constant current power supply. Keep the current constant and control the heat dissipation of the LED.

4. Grouping of LED lights. For example, in the case of 24 infrared rays, it can be arranged in 3 groups to reduce heat.

5, the choice of structural materials. For example, the LED light board and the outer casing are made of a material such as aluminum alloy which has a relatively good heat dissipation.

6. The application of the heat-conducting material, the heat-transfer material is used to conduct the heat of the heat-generating body to the shell, and then the heat is radiated by the natural convection method, thereby solving the problem well.

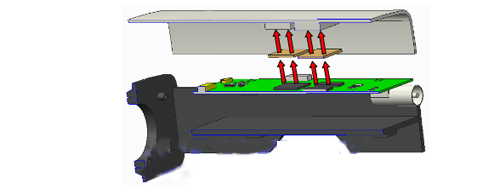

A board heat dissipation diagram - heat dissipation structure diagram:

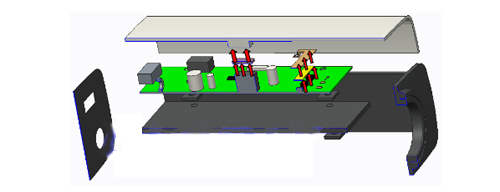

Power board heat dissipation diagram - heat dissipation structure diagram:

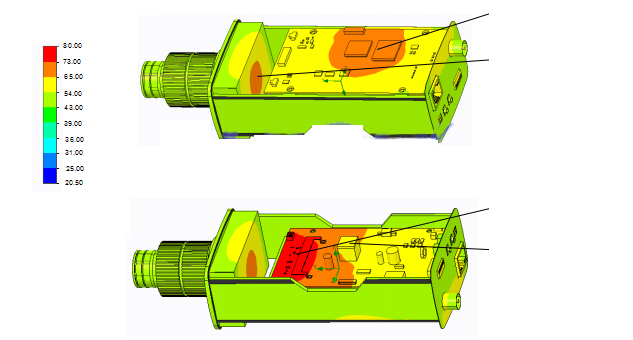

Temperature rise diagram 1:

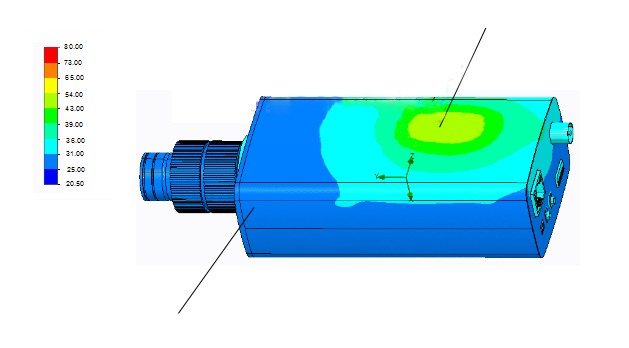

Temperature rise diagram 2:

Image processing module main heating chip and thermal material selection:

Want to see products Browse the major categories of products

View More>>>>Advisory If you are purchasing needs, please contact us

Consult from here>>>>Support Hotline

0769-82101656 Follow us