Service Hotline

0769-82101656

Wireless charging technology breaks the traditional connection line charging. It is a wireless charging technology that uses intelligent power on transmission to improve the efficiency and convenience of charging. In 2017, mobile phone wireless charging was widely recognized and its utilization rate is also increasing. It once became a popular product in mobile phone charging industry. Because of its small size, the working temperature of internal electronic components is The heat conduction silicon film provides the heat dissipation scheme.

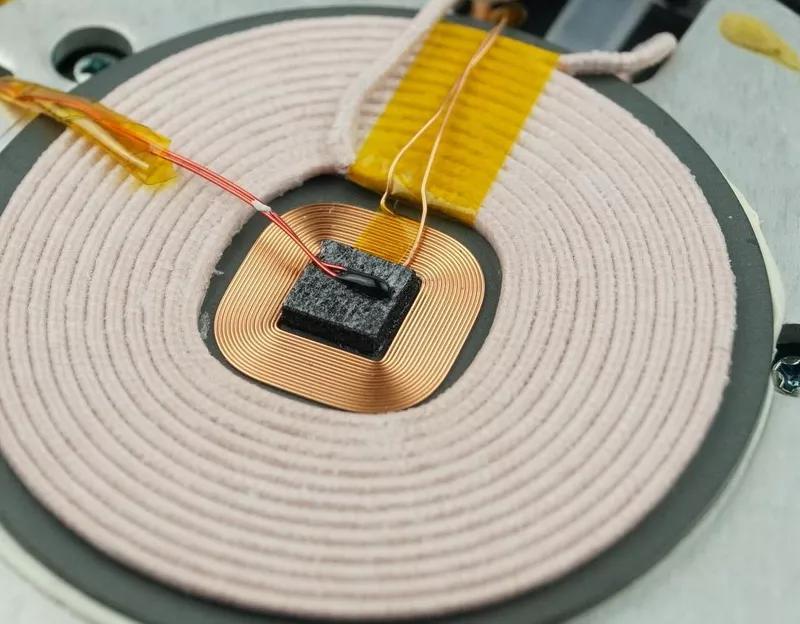

In order to make the heat dissipation efficiency better, the metal material with the wireless charging bottom as a whole plus the antiskid pad can lay a good foundation for the heat dissipation of the internal electronic components, and play a antiskid and wear-resistant effect. In the part of wireless charging inner coil, this part includes the middle part which is also the most concentrated part of heating. Therefore, a temperature probe will be installed in the middle of the coil to ensure that the charger's operating temperature is within the safe temperature range.

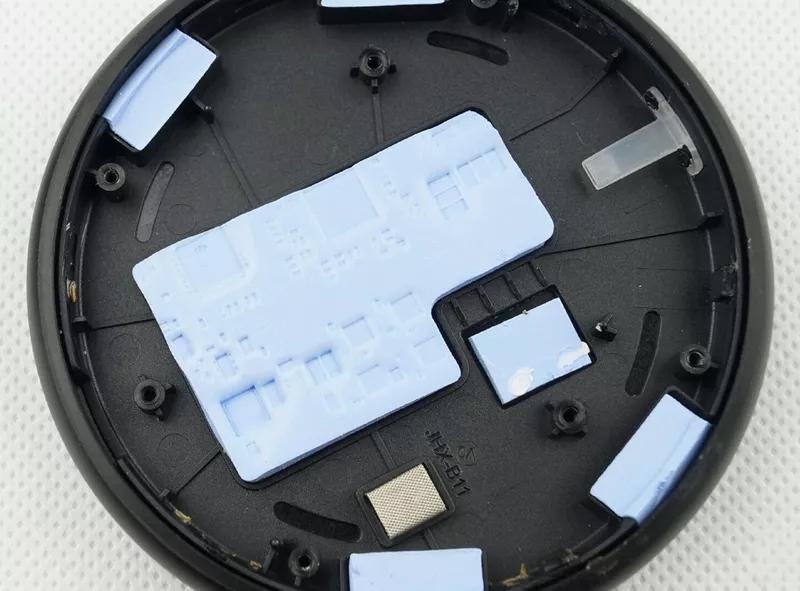

Remove the screws of the coil metal base plate, and you can see the internal structure of the bottom shell of the product. The bottom shell adopts the integrated metal forming, which is also the key to heat dissipation. The purpose of using metal is to better transmit the internal heat of the product through the bottom shell to the outside, so that the internal working temperature always handles the safe state, thus delaying the service life of the product.

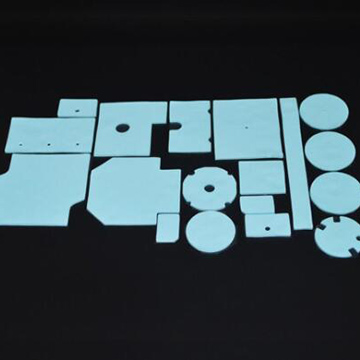

Because the circuit board with wireless charging is connected to the bottom shell, all components are concentrated on one side of the PCB, and the circuit board is an irregular whole, so there is no way to directly and seamlessly connect with the bottom shell, so the bottom shell is pasted with heat-conducting silica gel sheet and conductive foam to fill the gap between the bottom shell and the circuit board, so that the heat of the circuit board passes through the heat-conducting silica gel sheet and conductive foam Guide the bottom shell to dissipate heat, and also play the role of electromagnetic shielding.

Thermal conductive silica gel sheet has certain flexibility, excellent insulation, compressibility, and natural viscosity on the surface, which is specially produced for the design scheme of heat transfer by using the gap. It can fill the gap, complete the heat transfer between the heating part and the cooling part, and also play the role of insulation, vibration reduction, sealing, etc., which can meet the design requirements of miniaturization of equipment. It is technological and practical It is an excellent heat conduction filling material and widely used in electronic and electrical products. Heat conducting silica gel sheet is a kind of heat conducting medium, which is used to transfer the surface temperature of heat source to radiator or air.

Dongguan Gold-cool Nano Technology Co., Ltd., a national high-tech enterprise, has been insisting on independent research and development in the field of heat conduction and heat dissipation materials for many years, and has a number of patents. It is a high-tech enterprise integrating design, research and development, production and sales one-stop service. The company's heat conduction and heat dissipation products include: heat conduction silica gel sheet, heat conduction double-sided adhesive, heat conduction silicone grease, heat conduction mud, heat conduction potting adhesive, heat conduction silica gel cap cover, etc. Welcome to inquire: 400-6235-169

Want to see products Browse the major categories of products

View More>>>>Advisory If you are purchasing needs, please contact us

Consult from here>>>>Support Hotline

0769-82101656 Follow us